Auto Repair Shop In Plainfield, IL

How to Diagnose and Fix Rear End Differential Issues in Your Vehicle

When it comes to diagnosing and fixing issues with your vehicle, the rear end differential is often an overlooked component that plays a crucial role in ensuring a smooth and safe driving experience. James Thornton, a renowned automotive expert with over 30 years of experience, emphasizes the importance of this system by stating, "The rear end differential is vital for maintaining proper torque distribution and stability in your vehicle." Understanding how to identify problems within this mechanism can save drivers from costly repairs and enhance overall vehicle performance.

The rear end differential functions as the heart of your vehicle's drivetrain, allowing the wheels to rotate at different speeds while providing the necessary power to the rear wheels. Without proper maintenance or timely diagnosis, minor issues can escalate into significant mechanical failures. By familiarizing yourself with the symptoms of rear end differential problems—such as unusual noises, vibrations, or handling difficulties—you can take proactive steps to address them.

In this guide, we will delve into the diagnostic procedures and repair strategies for common rear end differential issues, empowering you to maintain the health of this essential component. Through expert advice and practical tips, you'll gain the knowledge to ensure your vehicle remains in peak condition, ready to face the road ahead.

Understanding the Role of the Rear End Differential in Vehicle Mechanics

The rear end differential plays a critical role in the mechanics of a vehicle, enabling it to effectively handle the diverse challenges of driving. It allows the rear wheels to rotate at different speeds, particularly when cornering. As a vehicle turns, the outside wheel travels a longer distance than the inside wheel; the differential compensates for this difference, promoting stability and smooth maneuverability. Without a properly functioning differential, drivers would experience increased tire wear, reduced traction, and a decrease in overall performance.

Additionally, the differential is responsible for distributing engine power to the wheels, aligning the torque applied to each side based on the vehicle’s demands. This distribution is essential for maintaining balance and control, especially on uneven surfaces. The differential also interacts with components such as the driveshaft and axles, making it an integral part of the driveline system. Regular maintenance and inspection of the differential are crucial in preventing more significant mechanical issues and ensuring the smooth operation of the vehicle. Understanding these functions can help drivers recognize early signs of differential problems, leading to timely diagnosis and repairs.

How to Diagnose and Fix Rear End Differential Issues in Your Vehicle - Understanding the Role of the Rear End Differential in Vehicle Mechanics

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| Noise from Differential | Grinding, whining, or clunking noises | Worn bearings, low lubricant levels | Inspect and replace bearings; check and refill lubricant |

| Leaking Fluid | Puddles of fluid under the vehicle | Damaged seals or gaskets | Replace seals and gaskets |

| Vibration while Driving | Shaking or wobbling felt from the rear | Unbalanced axle, worn U-joints | Balance the axle; replace U-joints |

| Poor Acceleration | Slow response when accelerating | Sticking or damaged clutch packs | Inspect and repair or replace clutch packs |

Common Symptoms of Rear End Differential Problems in Vehicles

When diagnosing rear end differential issues in vehicles, paying attention to common symptoms is crucial for identifying potential problems early on. One of the most noticeable signs of a differential issue is unusual noises emanating from the rear end, particularly during acceleration or deceleration. Drivers may hear grinding, whining, or clunking sounds, which can indicate worn gears or insufficient lubrication. Having these noises assessed promptly can prevent further damage to the differential.

Another key symptom is a noticeable vibration while driving, especially during turns or at higher speeds. This vibration may be caused by uneven wear on the differential gears or issues with the axle shafts. Additionally, if there are signs of leakage or pooling of fluid underneath the vehicle, it could suggest a compromised seal or gasket, leading to inadequate lubrication of the differential system. Recognizing these early warning signs can facilitate timely repairs and maintain the vehicle's performance and safety.

Step-by-Step Diagnostic Process for Rear End Differential Issues

When diagnosing rear end differential issues in a vehicle, a systematic approach is essential to identify problems effectively. Begin the diagnostic process by performing a visual inspection of the differential housing. Look for signs of leaks, cracks, or abnormal wear patterns on the gears. According to industry reports, nearly 30% of differential failures are attributed to insufficient lubrication, which can be identified by dark, contaminated oil. Checking the fluid level and condition should be one of your first steps, as this will provide critical information about the overall health of the differential.

Next, listen for unusual noises while driving, such as grinding or whining, which can indicate issues within the gears or bearings. Conduct a road test to monitor how the vehicle handles; any vibrations or slipping could signal deeper problems. A study from the Automotive Research Association highlighted that early detection through sound and vibration analysis can reduce repair costs by up to 25%.

Tips: Maintain regular service intervals for your differential fluid changes, as this helps prevent potential issues before they escalate. Additionally, invest in quality fluid designed for your vehicle's specific requirements to ensure optimal performance and longevity. Finally, if you notice persistent problems, consider consulting a professional to conduct a thorough inspection, as timely intervention can save you from more extensive repairs down the line.

Tools and Equipment Required for Rear End Differential Inspection and Repair

To effectively inspect and repair rear end differential issues, having the right tools and equipment is essential. Start with basic hand tools, including a set of wrenches and sockets to remove differential covers and components. A torque wrench is crucial to ensure all bolts are properly tightened to manufacturer specifications, which helps avoid future failures. Additionally, rubber mallets can be useful for gently tapping parts without causing damage, particularly when removing stubborn components.

For more in-depth inspection, specialized tools such as a dial indicator gauge can help measure gear backlash and ensure proper setup within the differential. A mechanic's creeper or work platform can make accessing the differential area more comfortable and safer. Don't forget safety equipment such as gloves and goggles to protect yourself during the inspection process. Finally, having a fluid extraction pump handy will assist in draining and refilling differential oil, ensuring the system is clean and properly lubricated. By equipping yourself with these essential tools and following appropriate procedures, you can effectively diagnose and address rear end differential issues in your vehicle.

Best Practices for Maintaining and Servicing Your Vehicle's Differential

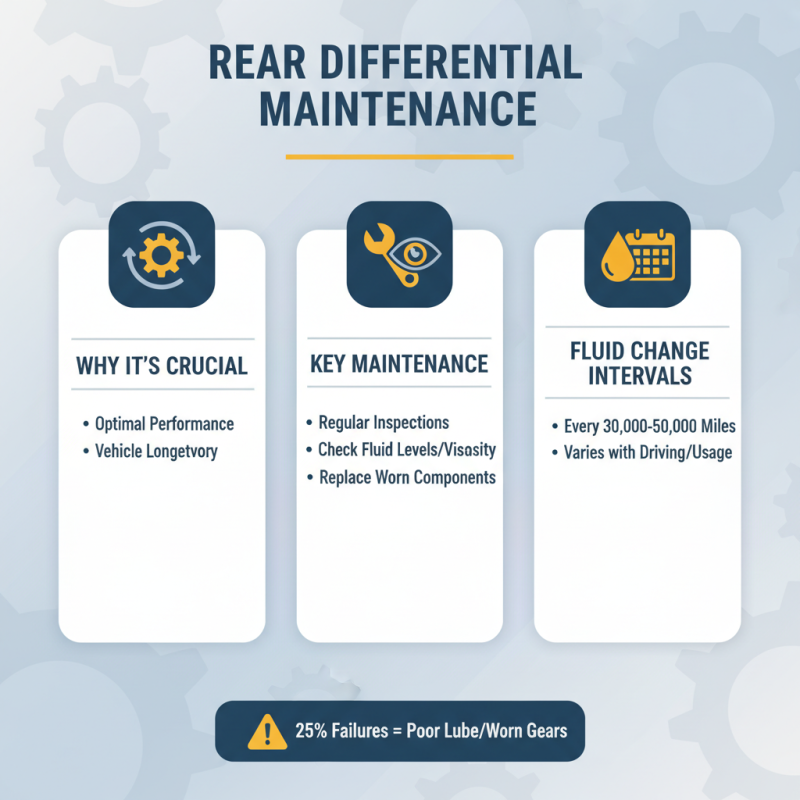

Maintaining and servicing your vehicle's rear end differential is crucial for ensuring optimal performance and longevity. Regular inspections are a cornerstone of good maintenance practices. Industry reports suggest that around 25% of differential failures can be traced back to inadequate lubrication and worn gear components. Checking fluid levels, ensuring the proper viscosity, and replacing the differential fluid at recommended intervals can significantly reduce the risk of issues. Most manufacturers suggest changing the differential fluid every 30,000 to 50,000 miles, but this can vary depending on driving conditions and vehicle usage.

In addition to fluid maintenance, it is essential to keep an eye on the differential's physical condition. Inspecting for leaks, listening for unusual noises during operation, and checking for any signs of wear or damage can help catch potential issues before they escalate. According to studies, a proactive approach to differential maintenance can extend its life by up to 40%, which ultimately saves on costly repairs. Implementing best practices such as regular servicing, utilizing high-quality lubricants, and adhering to a strict maintenance schedule can make all the difference in maximizing the performance of your vehicle's differential.

Related Posts

-

What is Differential Repair and How Does it Impact Your Vehicle Performance

-

2025 Top 10 Mobile Transmission Repair Services You Can Trust

-

Top 10 Benefits of Regular Tune Ups and Oil Changes for Your Vehicle

-

Essential Guide to Auto Repair Help for DIY Enthusiasts and Beginners

-

Explore the Future of Struts Cars: Innovations and Trends You Can't Miss!

-

How to Find the Best Car Repair Website for Your Auto Repair Needs

Contact Us

Service Area

Plainfield, 60585, 60544, 60586, Naperville, 60564, Bolingbrook, 60490, 60440, Romeoville, 60446, Will, Kendall, DuPage, Counties. Our auto repair shop in Plainfield, IL, has been serving the local area plus all surrounding Chicagoland since 1978.

Specialties

• Computer Diagnostic • Brake Shop • Engine Replacement • Transmission Rebuild • Clutch Replacement • Differential Rebuild • Suspension Shop • Steering • Shocks & Struts • Heating & Cooling • Electrical • Exhaust Shop • Catalytic Converter Replacement • Alignment • Domestic & Foreign Vehicle Service • Auto Repair In Plainfield, IL • Auto Repair Shops Near Me • Towing Service Near Me