Auto Repair Shop In Plainfield, IL

How to Effectively Repair Your Cooling System: Step-by-Step Guide

In the realm of automotive maintenance, the importance of a well-functioning cooling system cannot be overstated. According to a recent report by the Automotive Service Association, nearly 30% of vehicle breakdowns are attributed to cooling system failures. As such, understanding the nuances of cooling system repair is crucial for vehicle longevity and performance. This is highlighted by expert mechanic and industry analyst, Dr. Emily Johnson, who states, "Neglecting the cooling system can lead to severe engine damage, resulting in costly repairs that could have been easily avoided with proper maintenance."

Repairing your cooling system not only ensures optimal vehicle performance, but it also enhances fuel efficiency and reduces harmful emissions. The rising cost of engine repairs, noted in a 2023 study by the National Highway Traffic Safety Administration, emphasizes the necessity of addressing cooling system problems promptly. With an increasing number of vehicles on the road and more stringent environmental regulations, a proactive approach toward cooling system repair is essential for both vehicle owners and professionals in the automotive repair industry. This guide will walk you through the essentials of effectively diagnosing and repairing your cooling system, ultimately contributing to better performance and sustainability.

Understanding the Components of Your Cooling System

Understanding the components of your cooling system is crucial for effective repair and maintenance. A typical cooling system consists of several key parts, including the radiator, water pump, thermostat, and cooling fan. The radiator dissipates heat from the engine coolant, while the water pump circulates this coolant throughout the engine to maintain optimal temperature. The thermostat regulates the flow of coolant based on the engine's temperature, ensuring it operates within the appropriate range. The cooling fan assists in maintaining airflow through the radiator, especially at low speeds or when the vehicle is stationary.

Each component plays a vital role in the overall efficiency of the cooling system. For instance, a malfunctioning water pump can lead to overheating, as it prevents adequate circulation of coolant. Similarly, a stuck thermostat may cause the engine to run either too cool or too hot, both of which can result in engine damage over time. Understanding how these parts interact allows for better diagnostics when issues arise, making it easier to isolate problems and implement effective repairs. Regular checks of these components can help maintain system integrity and prolong the life of your vehicle.

How to Effectively Repair Your Cooling System: Step-by-Step Guide - Understanding the Components of Your Cooling System

| Component | Function | Common Issues | Repair Tips |

|---|---|---|---|

| Radiator | Disperses heat from the coolant | Leaks, blockages, corrosion | Inspect for leaks, flush to remove blockages |

| Water Pump | Circulates coolant through the system | Failures, leaks | Check for rust, replace if leaking |

| Thermostat | Regulates coolant flow | Stuck open/closed | Replace if not functioning properly |

| Cooling Fans | Helps cool the radiator | Failing fan motor, electrical issues | Test motor, check fuses and wiring |

| Hoses | Transport coolant | Cracks, leaks, swelling | Replace damaged hoses, ensure proper clamp tightness |

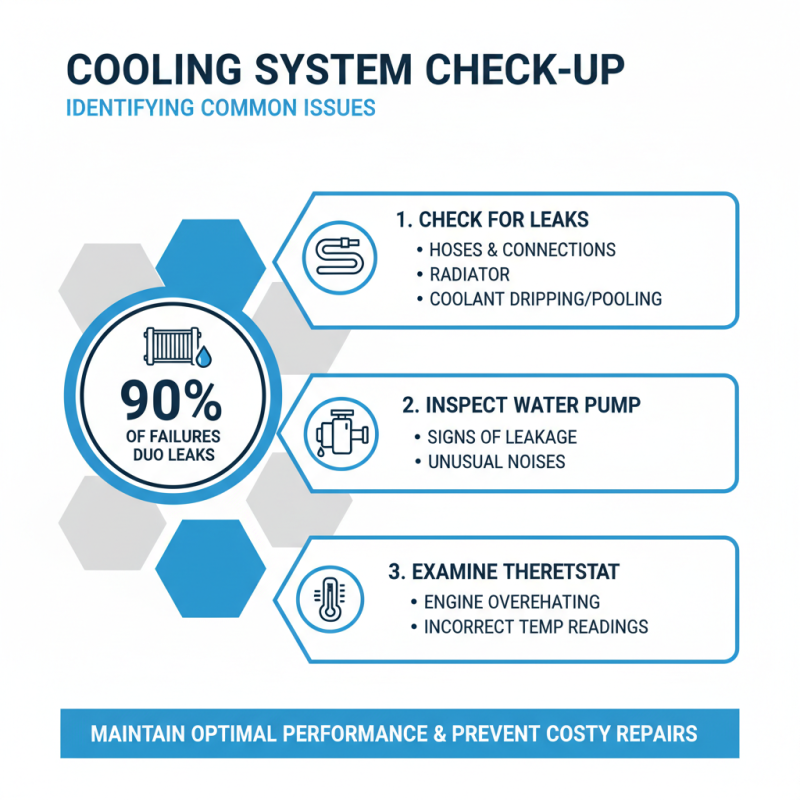

Identifying Common Cooling System Problems

Identifying common cooling system problems is crucial for maintaining vehicle efficiency and longevity. One of the most prevalent issues is overheating. An engine may overheat due to low coolant levels, a failing thermostat, or a malfunctioning water pump. Observing the temperature gauge on the dashboard can provide quick insight into this issue; a rise past the normal range should prompt further inspection of the cooling system.

Another common problem is coolant leaks, which can lead to a significant drop in coolant levels. Inspecting under the vehicle for puddles or stains can help identify leaks. Additionally, checking hoses and connections for cracks or wear can prevent further damage. It's important to address coolant leaks promptly, as they can lead to serious engine damage if left unchecked. Regularly monitoring the condition of the radiator and ensuring that the fans operate properly are also essential steps in maintaining an effective cooling system, as these components play a vital role in regulating engine temperature.

Step-by-Step Guide to Diagnosing Cooling System Issues

Diagnosing issues in your cooling system is crucial for maintaining optimal performance and preventing costly repairs. A common method for identifying problems is to check for leaks, as approximately 90% of cooling system failures are due to leaks, according to industry reports. Start by examining hoses, connections, and the radiator for any signs of coolant dripping or pooling. Ensure you also inspect the water pump and thermostat, as failures in these components can greatly affect the overall efficiency of your cooling system.

Another vital step in diagnosis involves monitoring the engine temperature. An overheating engine is often a sign of a malfunctioning cooling system. Use a reliable temperature gauge to keep track of your engine's operating temperature; anything above the manufacturer's recommended range signifies issues that need immediate attention. Additionally, look out for unusual sounds coming from the cooling fan or radiator area, as these can indicate mechanical failures.

Tips: Regular maintenance can enhance the longevity of your cooling system. Flush the coolant every two years to prevent sediment buildup and ensure proper functioning. Furthermore, inspect the coolant levels frequently – maintaining the correct coolant mix can help avoid overheating and extend the life of critical engine components.

Repair Techniques for Different Types of Cooling System Failures

When it comes to repairing a cooling system, understanding the different types of failures is crucial for an effective resolution. Common failure types include coolant leaks, compressor malfunctions, and clogged condenser coils. For coolant leaks, the first step is to identify the source of the leak, which may involve visually inspecting hoses and connections or using a pressure test. Once identified, repair can be done by replacing worn hoses or sealing minor leaks with appropriate sealants. Ensuring the system is recharged with the correct type and amount of coolant is essential for optimal performance.

In contrast, compressor issues typically manifest as strange noises or insufficient cooling. Diagnosing these problems often involves checking the power supply and electrical connections to the compressor before examining internal components. If necessary, individuals may need to replace the compressor, ensuring that the new unit matches the specifications of the existing system. Clogged condenser coils can significantly impede efficiency as well, and cleaning involves shutting off the system and gently removing debris using a soft brush or vacuum. Regular maintenance checks can also prevent this issue, keeping the cooling system running smoothly. By following these repair techniques tailored to specific cooling system failures, one can effectively restore functionality and efficiency.

Maintaining Your Cooling System for Longevity and Efficiency

Maintaining your cooling system is crucial for ensuring its longevity and efficiency. Regular maintenance not only helps in preventing costly repairs but also enhances the overall performance of your cooling system. One effective way to maintain your cooling system is by checking and replacing air filters regularly. Clogged or dirty filters can restrict airflow, causing the system to work harder and consume more energy. Ideally, filters should be inspected monthly and replaced every few months, or more frequently if needed, to keep the system running smoothly.

Another important maintenance task is to inspect the cooling system's coolant levels. Low coolant levels can lead to overheating and reduced efficiency. Regularly checking the coolant levels and topping them off, as necessary, will help maintain optimal performance. Additionally, cleaning the condenser coils is essential for maximizing efficiency. Dust and debris can accumulate on the coils, hindering heat exchange and forcing the system to work harder. It's advisable to clean the coils at least once a year to ensure the system operates effectively.

Lastly, scheduling professional maintenance can provide a comprehensive check-up of your cooling system. Technicians can identify potential issues and perform necessary repairs before they escalate. This proactive approach not only extends the lifespan of your cooling system but also ensures it runs efficiently, reducing energy consumption and lowering utility bills. By prioritizing these maintenance strategies, you can significantly enhance the lifespan and effectiveness of your cooling system.

Related Posts

-

Understanding the Essential Steps for Effective Cooling System Repair

-

Why Automotive Repair Programs Are Essential for Cutting Repair Costs and Enhancing Service Efficiency

-

Understanding Mobile Transmission Repair: Common Issues and Essential Fixes Explained

-

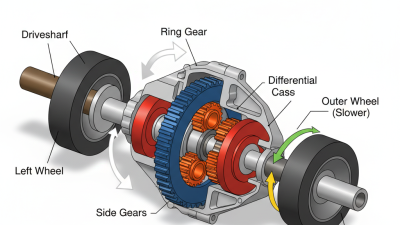

What is a Rear End Differential and How Does It Impact Your Vehicle Performance

-

Revolutionizing Your Skills: The Ultimate Guide to Auto Repair Programs for Beginners

-

Top 10 Benefits of Regular Tune Ups and Oil Changes for Your Vehicle

Contact Us

Service Area

Plainfield, 60585, 60544, 60586, Naperville, 60564, Bolingbrook, 60490, 60440, Romeoville, 60446, Will, Kendall, DuPage, Counties. Our auto repair shop in Plainfield, IL, has been serving the local area plus all surrounding Chicagoland since 1978.

Specialties

• Computer Diagnostic • Brake Shop • Engine Replacement • Transmission Rebuild • Clutch Replacement • Differential Rebuild • Suspension Shop • Steering • Shocks & Struts • Heating & Cooling • Electrical • Exhaust Shop • Catalytic Converter Replacement • Alignment • Domestic & Foreign Vehicle Service • Auto Repair In Plainfield, IL • Auto Repair Shops Near Me • Towing Service Near Me