Auto Repair Shop In Plainfield, IL

How to Perform Differential Repair for Your Vehicle Efficiently?

Differential repair can significantly impact vehicle performance. Understanding the process is essential for any car owner. Renowned expert in automotive mechanics, Dr. Adam Blake, emphasizes, "Proper differential repair ensures smooth driving and longevity." This technique deals with crucial components of your vehicle's drivetrain.

When addressing differential repair, attention to detail matters. Many assume it is straightforward, yet common mistakes occur. For example, improper fluid levels can lead to severe issues. Regular maintenance often gets overlooked, resulting in costly repairs down the line. Knowing when to seek professional help is vital.

Time is of the essence in differential repair. Delays can worsen problems, leading to more extensive damage. Pay attention to unusual noises or performance changes. However, don’t panic if you lack experience. Learning about this process enhances your ability to identify issues early. Becoming proactive about differential repair is a smart move for any vehicle owner.

Understanding Differential Repair: Key Concepts and Terminology

Differential repair is essential for maintaining vehicle performance. Understanding the key concepts and terminology can make repairs more efficient. The differential is crucial for transferring power from the engine to the wheels. It allows for smooth turns and adjustments in speed. A basic knowledge of the components involved helps in the repair process.

The differential consists of gears, bearings, and seals. Recognizing these parts aids in troubleshooting issues. Common problems include worn bearings or damaged gears. If you hear unusual noises or experience vibrations, it might be time to inspect your differential.

Tips: Always consult a repair manual. This will give you specific details about your vehicle's differential. Use appropriate tools for disassembly. Taking your time can prevent mistakes. Misalignment during reassembly can lead to further problems. Test the differential after repairs. Look for leaks or noises while running. Regular checks can save you from bigger issues down the road.

Preparing Your Vehicle: Tools and Materials Needed for Differential Repair

When preparing for differential repair, gathering the right tools and materials is essential. Start by ensuring you have a sturdy jack and jack stands. These tools stabilize the vehicle while you work. A socket set, wrenches, and pliers are crucial for removing components. Don't forget a drain pan to collect old fluid. Extra rags are handy for cleaning up spills.

Tips: Check your toolbox before starting. This prevents mid-repair runs to the store. Keep everything organized. Clutter can lead to misplacing important parts.

Next, you need differential oil, a new gasket, and seals. These materials ensure proper function and prevent leaks. A funnel makes pouring easy and cleaner. Some people overlook safety goggles. Protecting your eyes is just as important as having the right tools.

Tips: Take a moment to read instructions for any materials. Not all products are the same. Misusing them can lead to mistakes. Also, consider getting a friend to assist. Having an extra set of hands can make the process smoother.

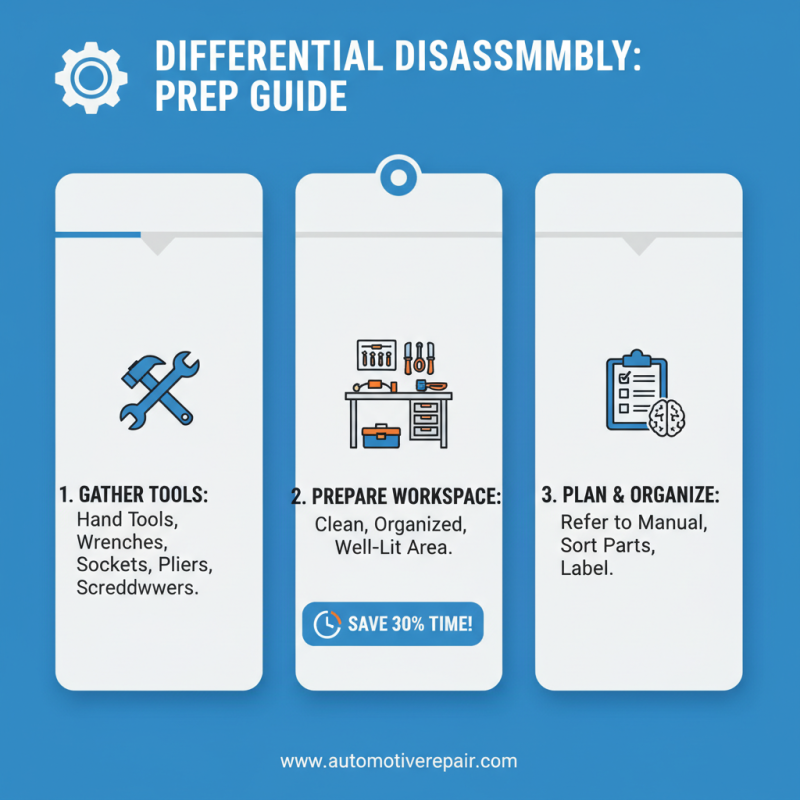

Step-by-Step Guide to Disassembling the Differential Assembly

Disassembling a differential assembly requires careful planning and execution. Begin by gathering your tools. You will need basic hand tools and a clean workspace. According to a recent industry report, proper organization can cut repair time by 30%. This is crucial for efficiency.

Start by securing the vehicle. Remove the wheels and brakes. Next, unbolt the differential cover. Expect some fluid to spill, so have a container ready. Some enthusiasts recommend wearing gloves, as differential fluid can be abrasive. Check for metal shavings or discoloration in the oil. These signs can indicate internal wear.

As you remove each component, document their order. Taking photos can help later during reassembly. Industry data shows that misalignment during assembly can lead to a 20% increase in failure rates. Carefully inspect the gears and bearings. Look for signs of pitting or wear. Reflect on any past mistakes during disassembly. Rushing this stage may lead to improper installation and costly repairs later. Remember, a methodical approach is key to a successful repair.

Inspecting and Diagnosing Common Differential Issues

Inspecting and diagnosing common differential issues is crucial for maintaining vehicle performance. The differential system allows for smooth turning while providing power to the wheels. Failure to address problems can lead to significant damage. A study found that about 30% of vehicles experience differential issues at some point.

Common symptoms include unusual noises, fluid leaks, and poor handling. A grinding noise may indicate worn bearings or gears. If you notice a puddle of fluid, it could mean a seal is damaged. Ignoring these signs often leads to costly repairs. According to industry reports, nearly 50% of differential repairs could have been prevented with early diagnosis.

Visual inspections are essential every few months. Look for signs of wear and check the differential fluid levels. If you're uncertain, consider consulting a professional. Many drivers overlook these checks, leading to preventable failures. Remember, being proactive about your differential can save you time and money in the long run.

How to Perform Differential Repair for Your Vehicle Efficiently? - Inspecting and Diagnosing Common Differential Issues

| Issue | Symptoms | Diagnosis Steps | Repair Method |

|---|---|---|---|

| Whining Noise | Unusual sounds during driving, especially when accelerating | Check fluid levels and inspect for metal shavings in the oil | Replace fluid and check bearings, replace if necessary |

| Leaking Fluid | Puddles of oil under the vehicle | Inspect seals and gaskets for wear or damage | Replace seals and gaskets as needed |

| Vibration | Excessive shaking while driving, particularly at higher speeds | Check the balance of the driveshaft and universal joints | Realign driveshaft and replace any damaged components |

| Overheating | Burning smell, and possible smoking | Monitor temperature; check for proper differential fluid | Flush the differential and replace fluid |

| Grinding Gears | Difficulty shifting gears, grinding noise during shifts | Inspect for worn gear teeth or improper engagement | Replace worn gears and ensure proper alignment |

Reassembling the Differential: Best Practices for a Successful Repair

Reassembling the differential is a crucial part of vehicle maintenance. Before you start, gather all necessary tools. Clean the components thoroughly. Dirt can lead to a poor seal and damage later. Apply a light coat of assembly lube to ensure smooth operation. This small detail can make a big difference.

Align the gears carefully. Misalignment causes wear and can lead to future failures. Take your time here; rushing can be costly. After placing the gears, check backlash with a feeler gauge. This step is often overlooked. A correct backlash ensures efficiency and longevity.

Next, tighten the bolts gradually. A torque wrench is essential to prevent damage. Observe the pattern of wear on the gears, if present. This can indicate underlying issues. Remember, if something doesn’t feel right during reassembly, revisit your steps. Sometimes, even the most experienced mechanics miss a detail. Keep an eye out for potential pitfalls.

Differential Repair Efficiency Metrics

Related Posts

-

What is Differential Repair and How Does it Impact Your Vehicle Performance

-

What is Differential Repair and How Does it Work?

-

How to Diagnose and Fix Rear End Differential Issues in Your Vehicle

-

10 Essential Tips for Finding a Reliable Mobile Car Technician

-

How to Perform a Tuneup for Your Car to Enhance Performance and Longevity

-

Essential Guide to Auto Repair Help for DIY Enthusiasts and Beginners

Contact Us

Service Area

Plainfield, 60585, 60544, 60586, Naperville, 60564, Bolingbrook, 60490, 60440, Romeoville, 60446, Will, Kendall, DuPage, Counties. Our auto repair shop in Plainfield, IL, has been serving the local area plus all surrounding Chicagoland since 1978.

Specialties

• Computer Diagnostic • Brake Shop • Engine Replacement • Transmission Rebuild • Clutch Replacement • Differential Rebuild • Suspension Shop • Steering • Shocks & Struts • Heating & Cooling • Electrical • Exhaust Shop • Catalytic Converter Replacement • Alignment • Domestic & Foreign Vehicle Service • Auto Repair In Plainfield, IL • Auto Repair Shops Near Me • Towing Service Near Me